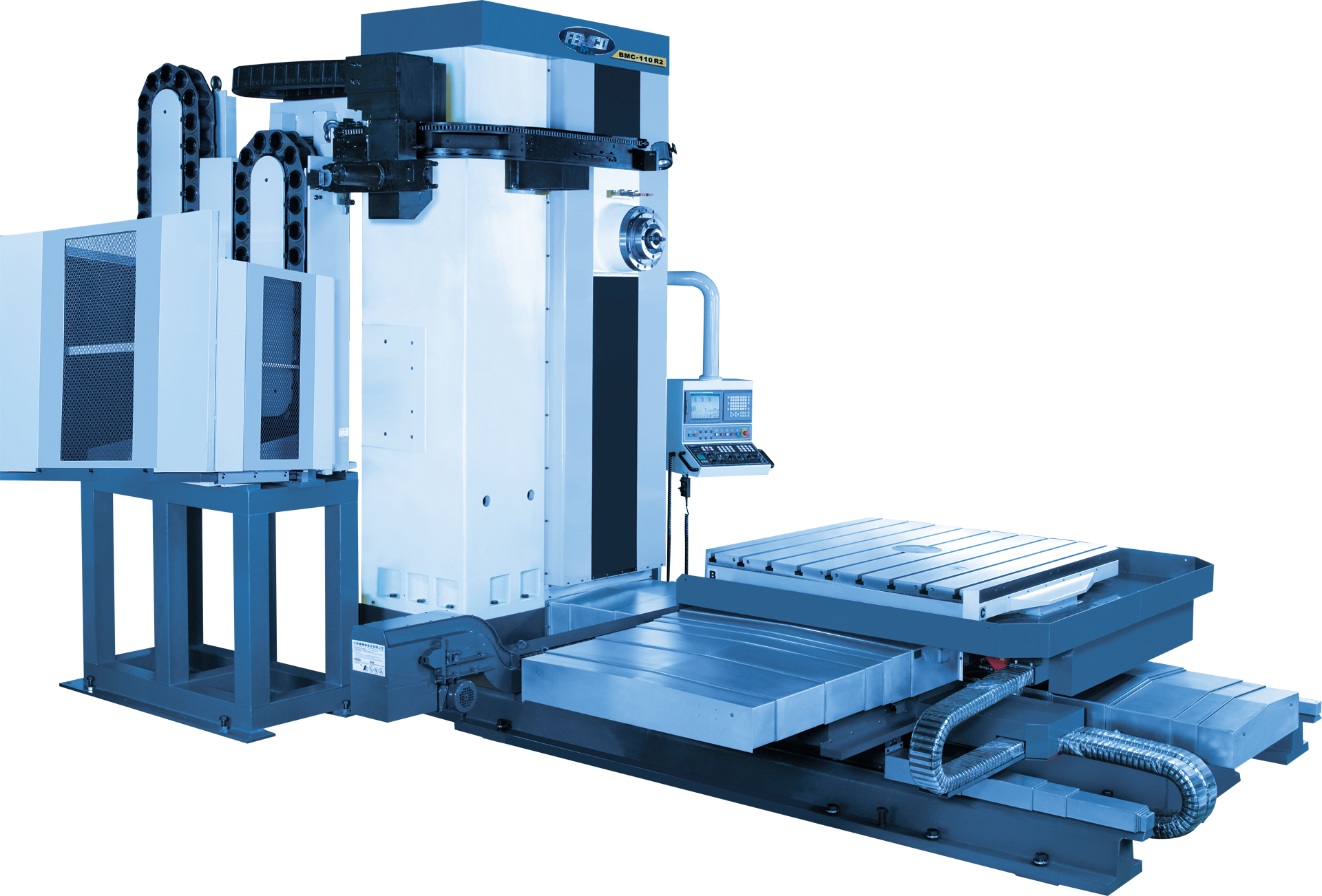

FST America | Machinery Division BMC-Series is a full line of Horizontal Boring Mills with 10 distinctive models. Featuring full 4th Rotary Axis tables; heavy table load capacities; extended reach of W-Axes. Each model provides specific capabilities for machining of large, complex parts.

[product-catalogue id=’1′]