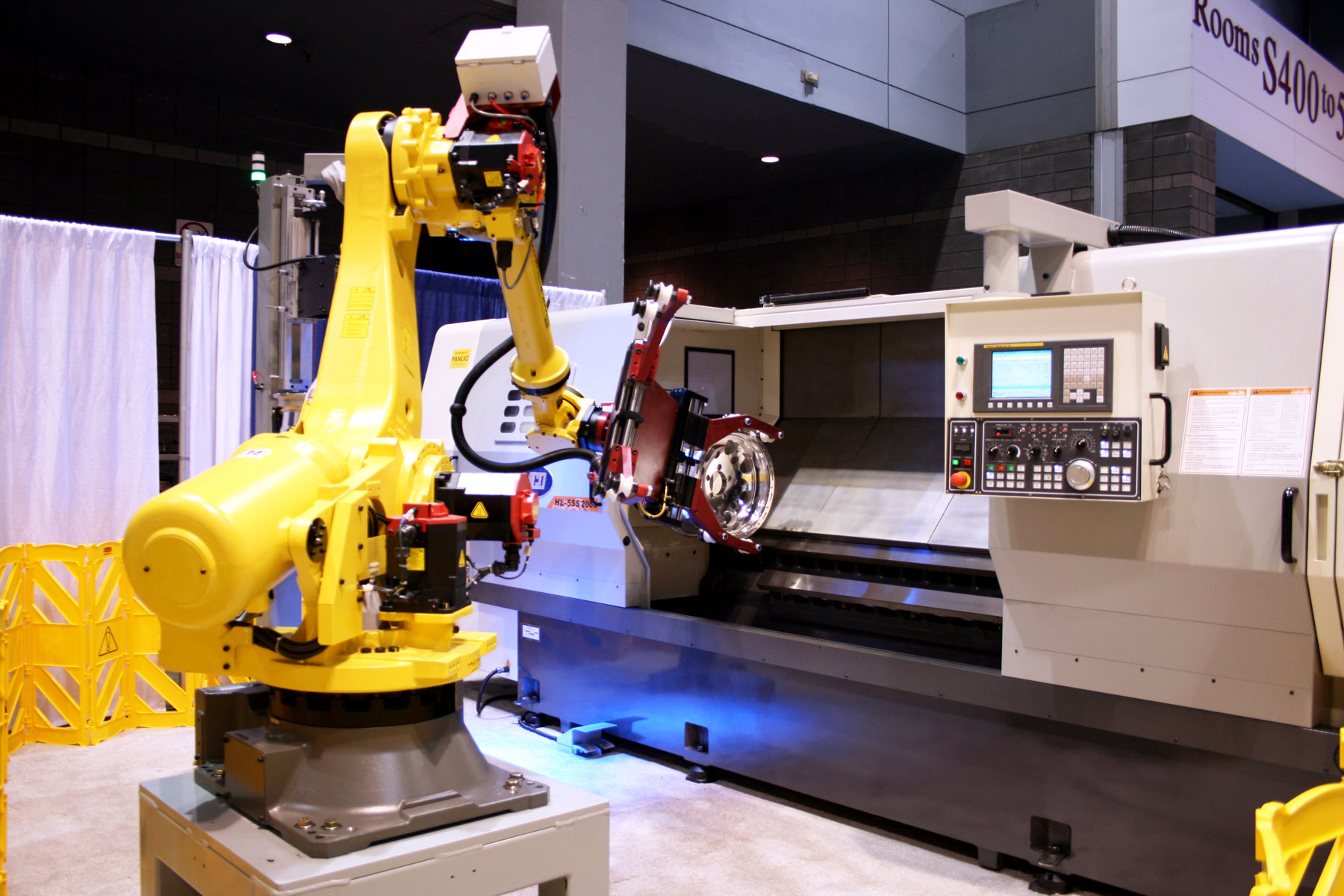

FST America | Machinery Division Wheel Machines for high volume production of wheels of superb quality. Models available for all aspects of wheel machining from machining specifically designed for turning exquisite mirror finishes to 5-Axis Wheel Drilling Machines for drilling the Lug Nut and Valve Stem Holes quickly and efficiently.

[product-catalogue id=’3′]